Manufacturing SPC Hybrid Flooring

SPC Hybrid Flooring can fast and easy to install, this flooring is engineered for exceptional durability and efficiency, enabling a markedly expedited installation process in comparison to conventional click systems. The innovative locking mechanism guarantees that each plank fits securely without the necessity of adhesives or nails, making it an optimal choice for both professional installers and DIY enthusiasts. Furthermore, the lightweight composition of the planks enhances ease of handling during installation, thereby minimizing labor time and effort.

SPC Hybrid Flooring has high fire resistance and flame retardant properties.

SPC Hybrid Flooring According to official statistics, 95% of the victims who were burned in the fire were caused by toxic gases.

SPC Hybrid Flooring fire rating is NFPA b, flame retardant, spontaneous combustion. If exit the flame in 5 seconds, it will extinguish and not produce toxic substances and gases.

SPC Hybrid Flooring has high wear resistance.

Waterproof SPC vinyl flooring wear-resisting revolutions can reach about 10,000 revolutions or even higher. The wear-resisting strength is more than several times higher than ordinary laminate flooring.

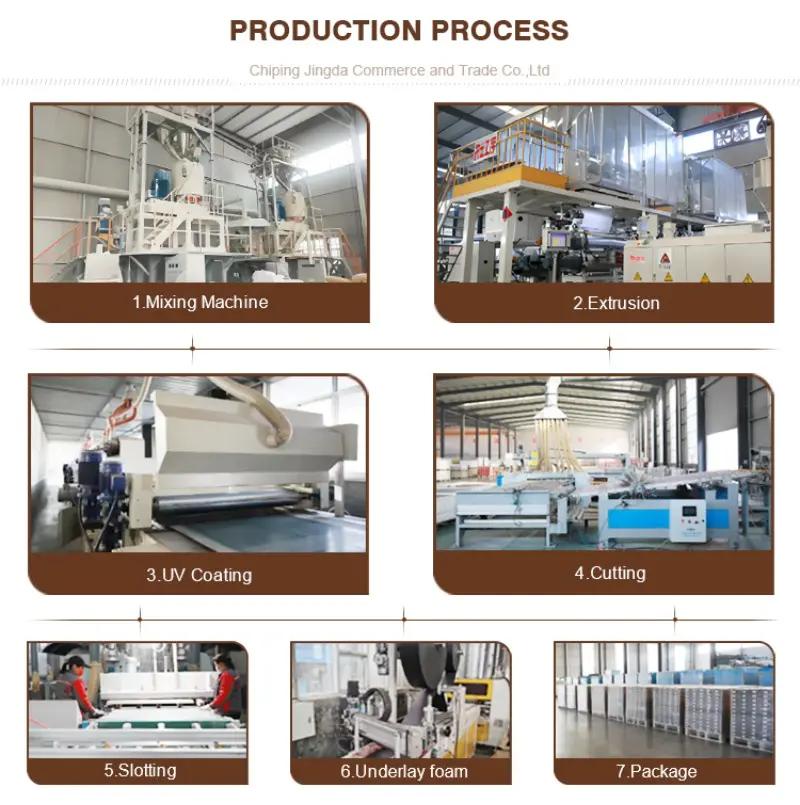

Product Process

Mixing: A meticulous blend of PVC and calcium powder is undertaken in a precise 1:3 proportion, with a catalyst expertly incorporated to initiate the chemical transformation.

Extrusion: The wear-resistant layer, adorned with a decorative paper, is expertly fused with the freshly extruded SPC substrate through a high-temperature and high-pressure lamination process. This results in a seamless, elongated SPC board, which is then cut to the desired lengths. A crucial step follows, where the boards are left to acclimate for 1-2 days, allowing them to attain equilibrium with their surroundings, thereby minimizing post-slotting deformation.

UV Coating: To enhance durability, a primer is initially applied and cured using ultraviolet (UV) light. This is followed by the application of a topcoat, which is again cured with UV light for added resilience. A subsequent cooling phase using cold water ensures the boards maintain their individuality, preventing any unwanted adhesion.

Cutting and Slotting: Simultaneous cutting and slotting techniques are employed, starting with the longitudinal edges before proceeding to the shorter sides, ensuring accuracy and efficiency in the manufacturing process.

Underlay Foam: To augment the floor's acoustic properties, an underlay foam is integrated. Among the options, IXPE (cross-linked polyethylene) foam is preferred due to its superior noise dampening capabilities compared to EVA (ethylene-vinyl acetate) foam.

Packaging: The final touch involves carefully packaging the fragile SPC boards in robust outer boxes and securing them on pallets, guaranteeing their safe transportation and preservation from potential damage.

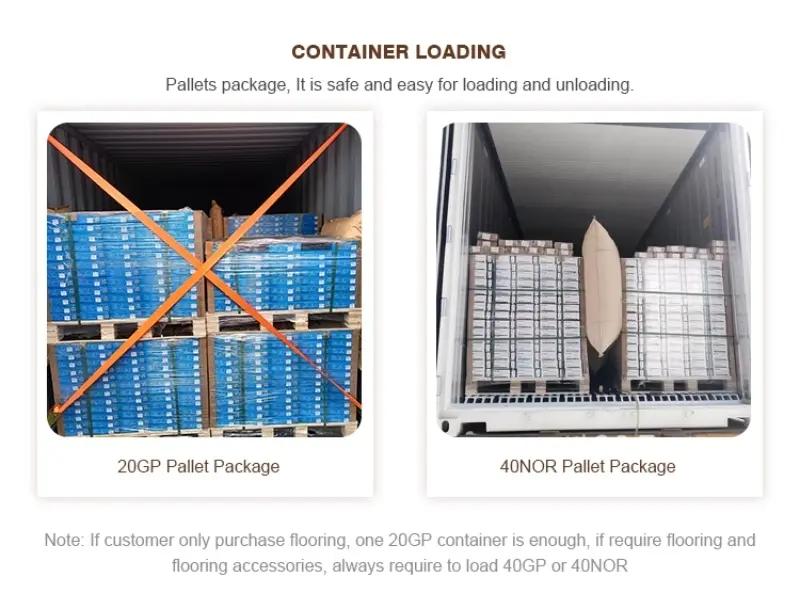

Packing and Shipping

The SPC flooring package is carton box, packing box can be customized based on the MOQ .

And then put the boxes into the pallet, pallets is safe for loading and unloading.

If customers only purchase flooring, it is enough to choose 20GP container. If customers purchase flooring and flooring accessories, it is usually to load 40GP or 40HQ.