Relief Laminated Flooring

The standard reinforced floor surface should all contain aluminum oxide wear-resistant paper. It weighs 46 grams, 38 grams, 33 grams, and even lower, directly sprayed with aluminum oxide on decorative paper. According to national regulations, the surface wear-resistant revolution of indoor reinforced flooring should be above 6000 revolutions, and only a floor with 46 grams of wear-resistant paper can meet the requirements. The wear-resistant rotation speed of 38 grams of wear-resistant paper can reach 4000-5000 revolutions, and 33 grams is even lower.

Advantage

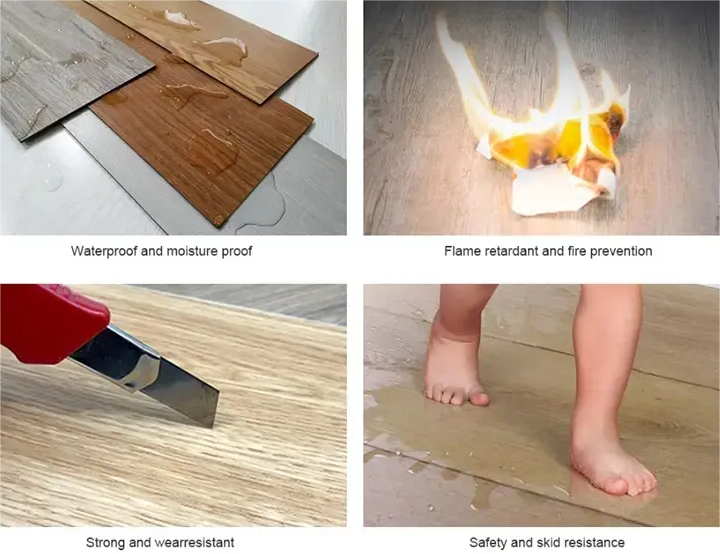

Laminate wood flooring offers superior strength and protection. It starts with a clear protective layer of UV-cured lacquer infused with aluminum oxide, which forms the first line of defense.

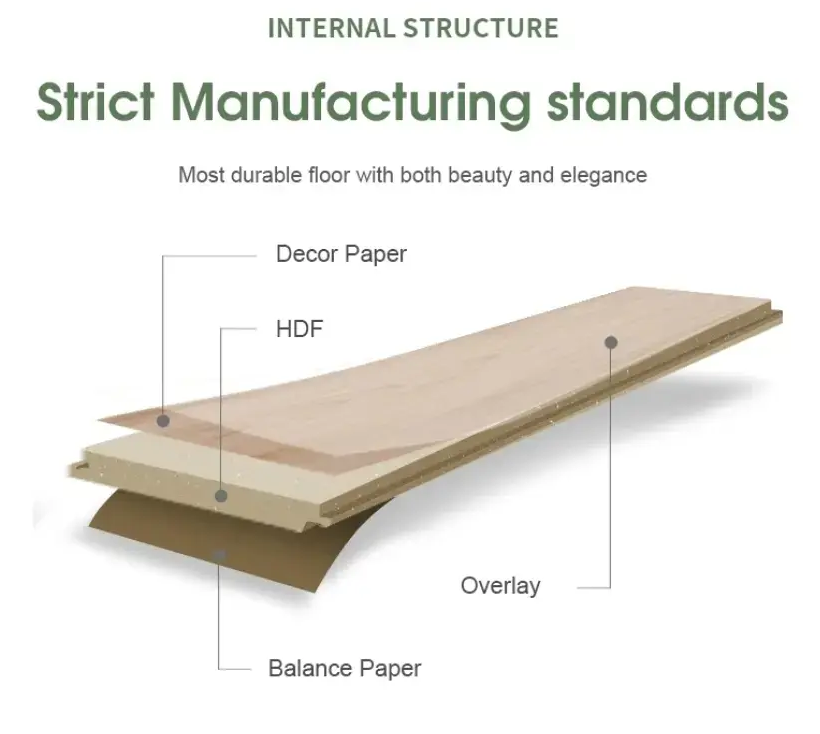

This layer effectively resists scratches, abrasions, and prevents fading caused by direct sunlight, ensuring long-lasting beauty for your floors. Beneath this durable surface, decorative paper and a high-density fiberboard (HDF) core create the realistic appearance of wood or stone, complete with authentic coloring and natural grain patterns.

Moreover, this robust construction enhances the flooring's stability and firmness. The addition of a locking layer and a balance layer facilitates easy installation and ensures better dimensional stability, making laminate flooring a practical and durable choice for any space.