Stone Plastic Composite Material Flooring

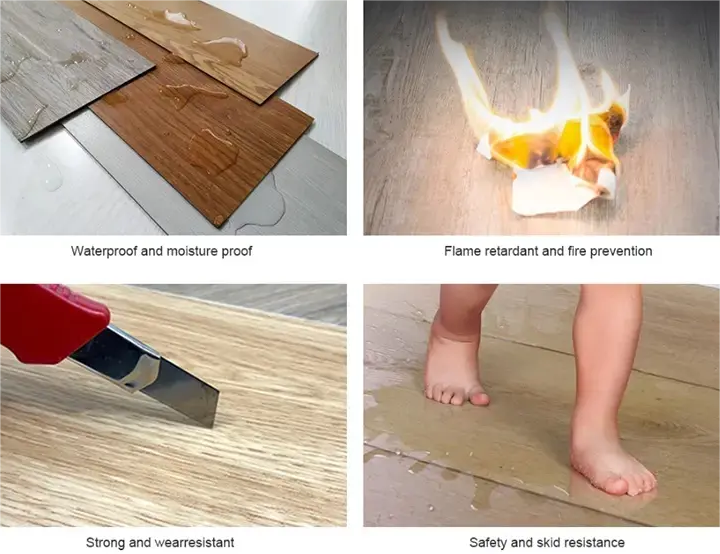

The manufacturing process of SPC flooring does not use glue and adopts a locking installation method, which avoids the formaldehyde problem that glue may bring, making it more environmentally friendly and convenient. This type of floor not only has diversified designs in color and texture, but also has excellent adhesion, impermeability, crack resistance, frost resistance, chloride ion penetration resistance, impact wear resistance, and aging resistance. It can form a dense, elastic, impermeable, and frost resistant "thin shell" on the surface of concrete, which not only serves as a surface repair, but also has good protective effects.

SPC Flooring

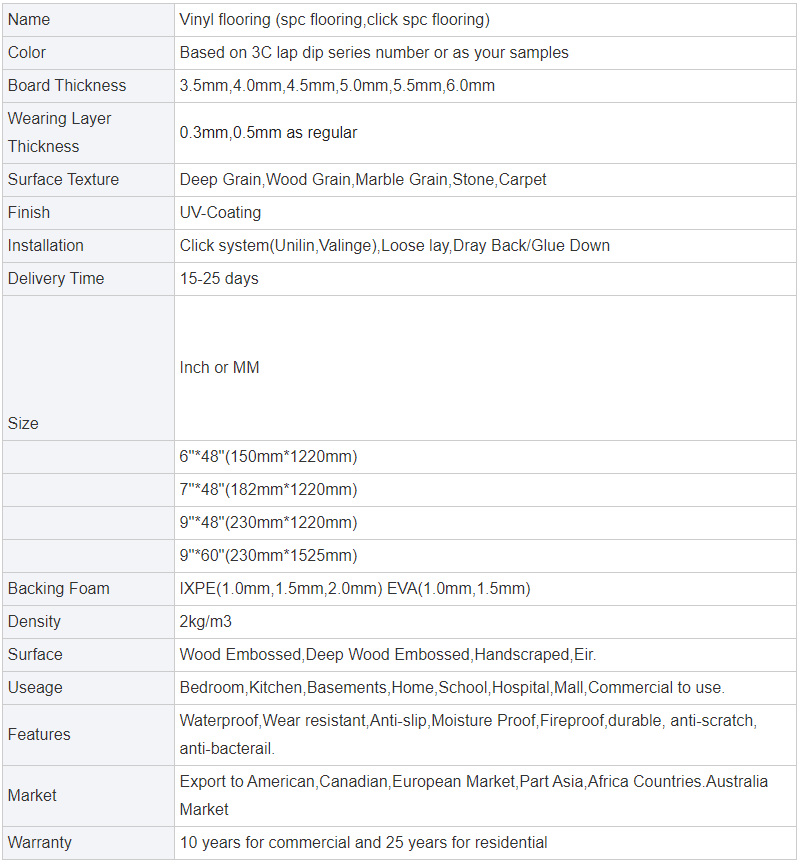

SPC is a material based on polymer PVC resin and natural stone powder, also known as stone plastic flooring or stone plastic composite flooring. It is mainly composed of PVC wear-resistant layer, PVC color film and substrate, and is made through a one-time heating bonding and embossing process. The characteristics of SPC flooring include zero formaldehyde, moisture resistance, mold resistance, fire resistance, insect resistance, and waterproofing. It is also easy to install and has a service life of over 30 years. twelve

The core layer of SPC flooring is mainly made of natural limestone powder, polyethylene (PE), and stabilizers through high-temperature extrusion, which has a harder core layer, making it harder and more stable. Compared with PVC flooring, SPC flooring differs in material composition and structure. PVC flooring, also known as soft plastic flooring, is mainly composed of polyvinyl chloride and plasticizers, and has good elasticity and softness.

Product details

Factory

Application location